The installation of Computer Tomography (CT) scan machines requires careful preparation and consideration to ensure smooth operation. We will discuss some important steps you should take to properly prepare a room for the successful installation of your new machine.

Planning

Before beginning your preparation for a CT scan machine installation, you must have a detailed plan and layout of how you want things set up. You should talk with professionals about power requirements and special considerations like odor elimination systems or noise-reduction curtains.

Additionally, be sure to contact city/state health authorities if needed to obtain building permits or other relevant documents related to equipment registration and safety protocols.

Space Requirements

The size and shape of the space available must be carefully evaluated prior to installation. This includes measuring both width and length as well as checking ceiling heights.

Additionally, it is important that at least two walls remain open so that technicians are able to access necessary components during maintenance or repair.

The Scan room should be typically around 27 feet by 15 feet in size and must be an open space for a table, scanner, room techs, and patients to move around.

the height of the ceiling should be at least 9 feet to 10 feet high to provide sufficient space for the installation of the CT scanner equipment and accommodate sufficient head clearance. The exact height can vary depending on the scanner model, type of room construction, and local building codes and regulations, so it’s best to confirm the requirements with the manufacturer before installation.

The Standard layout for the CT SCan installation is as per the AERB.

- Double Leaf door lined with 2.0 mm lead.

- Service Door Lined with 2.0mm lead

- All walls of the Examination Room are 23cm(9”)thk made of bricks.

- Viewing Glass window 100cm X 80cm of 2.0mm lead equivalence.

- CT Gantry, Examination Table, 4 Control Unit.

Power Supply and Network Connections

Ensure the steady power source before installing CT Scan Machine. Usually from an electrical outlet on one wall with enough amperage overload capability upon startup without causing damage or failure.

Additionally, Testing of the network connections such as Ethernet Cables ahead of time by contacting IT department personnel. Since most systems require Internet connectivity nowadays in addition to other physical inputs/outputs.

Environmental Factors and Considerations

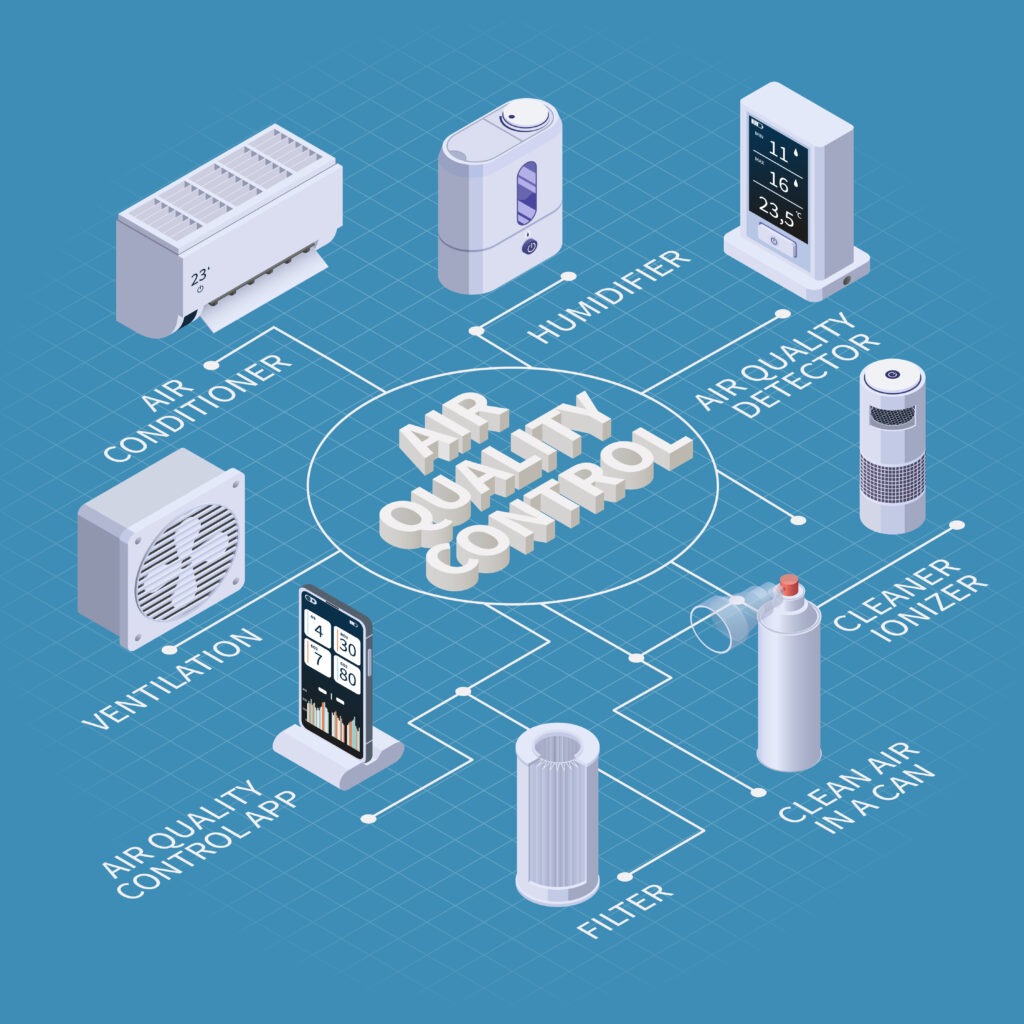

Proper ventilation within the CT Scanner room is vital. Otherwise, mechanical parts may overheat which can lead to significant damage without proper airflow throughout all areas inside while functioning correctly.

Furthermore, noise reduction measures are essential too since bright light sources produce considerable amounts. Even when quiet modes are there often affect nearby staff members negatively. Unless designated soundproofing implementation takes place accordingly to local regulations involving healthcare settings.

How to maintain the room temperature of a CT Scan Machine in Different Seasons?

A CT scan is a high-tech medical imaging device that relies on precise temperatures maintained in the environment. In order for the scans that it produces to be accurate, room temperature must be kept stable throughout all seasons.

Here we will discuss how to maintain the room temperature of a CT scan machine in summer, winter, and during the rainy season.

Temperature

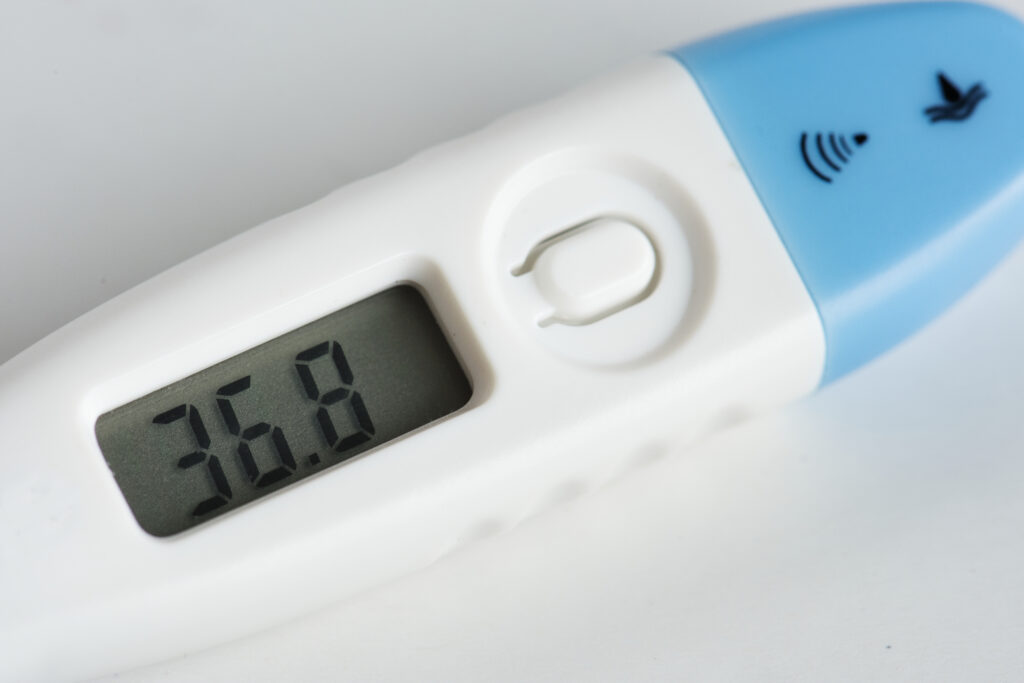

Maintenance of proper temperature is a must in the CT Scan room. The operating temperature in the CT scan room should be kept as close as 72° F (22.22°C)and it should never exceed 75° F (23.88°C).

Also, it should never fall below 64° F(17.77°C). The CT scanners generate heat during their use, so make sure the HVAC is fully operational on each scan day.

(Heating, Ventilation, Air Conditioning)

Humidity

The Humidity of the room is also a very important thing. The standard OEM(Original Equipment Manufacturer) recommendation is that the room be kept between 30% and 70% relative humidity. If the percentage exceeds 70 you risk moisture damage to the electronic components of your CT.

The Cables, Boards, and connector should be kept free of condensation. If the HVAC system is having trouble keeping humidity levels low, you may want to consider putting a stand-alone dehumidifier in the scan room.

Summer :

In hot weather conditions, it is important to ensure the CT scanner stays cool enough. Keeping the air conditioning running constantly or by using fans around the equipment, helps in cooling.

To keep heat away from the scanning area use blinds or curtains over windows and avoid positioning scanners close to sources of artificial heat. Additionally, it’s important to regularly change air filters in order to prevent dust from blocking the airflow or causing damage.

Lastly, keep an eye out for any signs of heat-related issues such as accelerated wear on parts or smoke coming from electrical components. These could indicate an impending malfunction that requires emergency assistance immediately.

Winter:

Keeping rooms cold can be expensive so you need to ensure your heating system is timing itself efficiently. Based on when your healthcare facility needs the warmest temperatures, it is set.

When running a CT scan machine in cold weather conditions it is imperative that sources of draught and external circulation are excluded. Condensation may form inside forming frost patches over electronic components due to radiated heat triggering high humidity levels.

This could cause irreparable harm resulting in costly damages down the line unless there is repair by specialist professionals.

Rainy Season:

Moisture problems can arise during rainy seasons too. During rainstorms and other wet weather days external ambient humidity should remain under control due to their impact on electronic parts subjecting them to corrosion damage.

Moisture seepage causes condensation within the components if there is a compromise in protective coatings, and it directly affects the results obtained.

When installing a new unit fuse box indoors make sure to fill the moisture-collecting insulation layers with non-polar fluids (such as silica gel). It must be before 6 feet around each appliance location including any joins. Also, ensure water does not trickle into fuses via wall openings originally made for conduit piping purposes only.

This proactive method ensures adequate protection against possible short circuits resulting from damp conditions, prevailing outdoors which may possibly seep through ventilation duct gaps otherwise dissolving away indoors without leave taken.

Cleanliness in CT Scan Room

The CT scan machine room must be kept clean and dust-free. If there is dust it may burn outboards, clog, fans, and other electrical equipment, and also bind the other moving parts.

By following these helpful tips outlined above, you will be better equipped with maintaining ideal operating temperatures for CT scans.

Taking certain steps such as monitoring humidity levels indoors as well as installing extra insulation layers helps improve overall safety procedures. while preventing possible damages caused by extreme temperatures rise.

How to maintain the humidity of the CT Scan Machine room in the Summer/ Winter/Rainy Season?

Maintaining the humidity of a CT Scan machine room is an important task, especially during seasonal changes. It’s important to control the temperature within certain boundaries as even minor fluctuations can negatively affect it.

There are various ways one can maintain the right amount of humidity for each season

– using air conditioners or humidifiers depending on whether you want warmer or cooler temperatures accompanied by higher or lower levels of moisture respectively.

– Moreover, installing dehumidifiers helps reduce excessive amounts of dampness from forming within your facility. Helps better control overall environmental factors and creates safer health standards for equipment and staff alike.

– For extremely humid conditions during these months adding fans or other ventilation systems may also prove beneficial.

Most manufacturers recommend that for optimal accuracy, the temperature within your CT scanner’s room should remain between 72°F (22°C), with a maximum temperature of 75°F (24°C) and a minimum temperature of 64°F (18°C)

Humidity

The standard OEM recommendation is that the CT scanner room be kept between 30 and 70% relative humidity. If the percentage exceeds 70 you risk moisture damage to the electronic components of your CT.

The cables, Boards and the connector should be kept free of condensation. If the HVAC system is having trouble keeping humidity levels low, you may want to consider putting a stand-alone dehumidifier in the scan room.

In addition, a CT scan suite requires mechanical ventilation, and it requires particular care with regard to the control room and scan room. There must be a humidifier on site to maintain proper humidity in the room. The use of humidifiers in a CT scan room can help to control the humidity levels and maintain them at an ideal range, thus, helping to protect the equipment and the individuals working in the room.

HVAC- Heating, Ventilation, and Air Conditioning.

In conclusion, ensuring the ideal space, temperature, and humidity within a CT scan room is crucial for optimal imaging outcomes and patient comfort. By maintaining a controlled environment, healthcare facilities can minimize potential equipment malfunctions, enhance image quality, and provide a more pleasant experience for patients.

Monitoring the room’s temperature and humidity levels regularly, investing in proper ventilation systems, and implementing effective insulation measures are key steps to creating an optimal environment for CT scanning. By prioritizing these factors, healthcare providers can enhance the accuracy and efficiency of CT scans, ultimately benefiting both patients and medical professionals.